Custom Manufacturing Services

Your Overseas Manufacturing Partner

If you want a simpler way to manufacture your next product, choose GPI for turn-key custom manufacturing services. Partner with our team to save time, avoid delays and meet deadlines, stay on budget, and prevent mistakes!

We’ll guide you through the manufacturing process from start to finish—we’ve been managing projects for customers for over 40 years.

Custom Manufacturing Services

GPI’s expertise spans a variety of manufacturing processes, including printing, plastic molding, die casting, vacuum forming, textiles, and metal stamping.

Have a complex assembly? No problem. Our team has experience with products that have complicated assembly requirements. We’ll pay attention to every detail to deliver a high-quality product every time.

Plastic Molding

A cost-effective solution for a wide range of products. GPI capabilities include injection molding, compression molding, blow molding, rotational molding, and extrusion molding.

Common plastic molding materials include acrylic, PVC, polypropylene, polystyrene, and ABS.

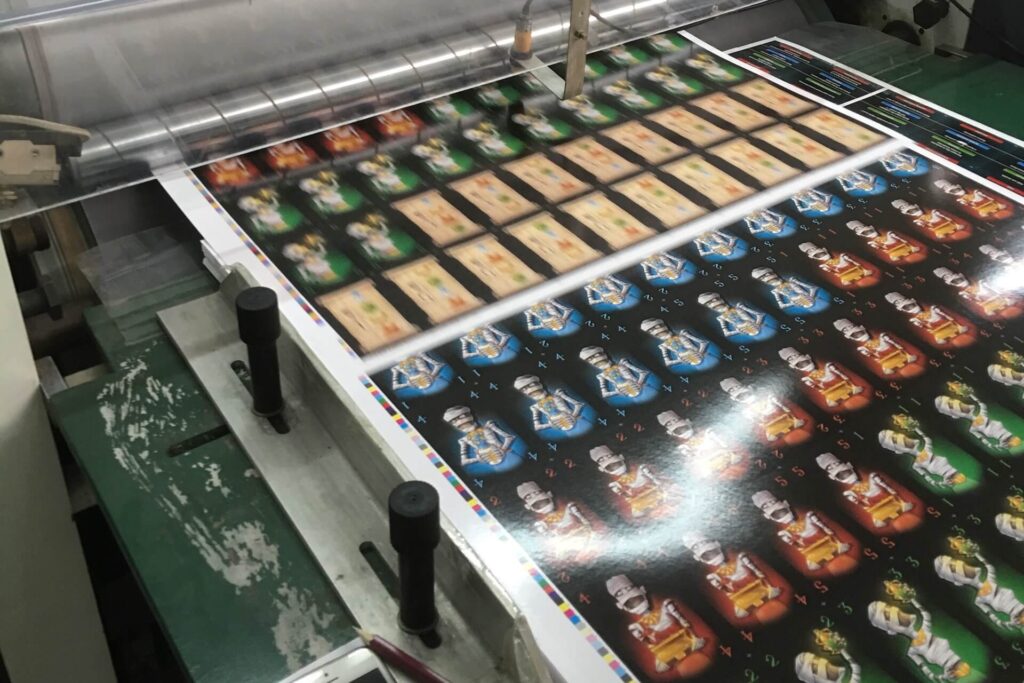

Printing

A secondary process that adds aesthetic value or provides additional information for a product. Applications include text, graphics, designs, patterns, instructions, and labels to make your product and retail packaging stand out.

GPI capabilities include litho, silkscreen, heat transfer, hot stamping, tampo/pad, and dye sublimation printing.

Manufacturing with Textiles

Common materials in textile manufacturing include cotton, nylon, and mesh.

We’re experienced with silkscreening and digital printing on fabrics, sourcing and custom manufacturing plush, and storage bags in a variety of materials and styles.

Vacuum Forming

Used primarily for the production of lightweight plastic components. During vacuum forming, the material is placed over a mold and heated until it becomes flexible. Vacuum pressure is then applied to shape the material against the mold.

Vacuum forming is a great solution for securing and displaying products in retail packaging.

Die Casting

A manufacturing solution to create molded components out of metal. The metal is heated until it becomes molten and then poured into a steel mold.

Die casting is commonly used for aluminum, copper, bronze, brass, and other alloys.

Metal Stamping

Think of metal tins used for retail packaging. Tooling bends and presses metal into a three-dimensional form. This method is cost-effective for larger production volumes.

We’re very experienced with creating custom shapes and printing directly onto metal.

GPI’s Manufacturing Process

Customers partner with GPI to avoid the headaches of overseas manufacturing. It can be difficult to know which factories to work with, how to ensure they manufacture your product exactly as needed, and what it takes to oversee quality and stay on schedule.

GPI is highly experienced with working with factories overseas—we visit the factories we work with and know their people and processes inside out!

Here’s how our process works:

- Submit your product specifications to us. This could be the proverbial “cocktail napkin sketch” or highly detailed CAD files and 3D models.

- We’ll finalize your product design with you and provide a custom manufacturing quote.

- We’ll select a manufacturer from our carefully vetted network and communicate all of your requirements.

- You’ll receive preproduction samples for your approval. We don’t authorize our factory partner to commence production until you’re satisfied.

- We’ll manufacture your product as soon as you’re ready to proceed.

- You’ll receive postproduction samples to approve before your products are delivered to the overseas shipping port.

- We can also coordinate product safety testing and arrange to ship your products anywhere in the world.

You’ll have a dedicated GPI team of representatives who will proactively manage your project, communicate updates, and answer questions every step of the way.

Why Choose GPI for Custom Manufacturing Services?

Personal Relationships with Overseas Manufacturers

We maintain close relationships with an intentionally small network of factories in China and Vietnam. We do not put projects “out to bid” to dozens of unknown factories.

Instead, we partner with manufacturers that we have known personally for decades. We visit their factories, meet with their production planners and quality control teams, and work collaboratively to ensure attention to detail and adherence to control is their top priority.

Project Management from Start to Finish

The product manufacturing process has hundreds of moving parts that must all work together to deliver a quality product on budget and on time.

Our comprehensive project management can help you avoid the common pitfalls of custom manufacturing: sourcing issues, supply chain delays, defective products, shipping challenges, and more.

Expertise in a Wide Range of Manufacturing Solutions

Our team can guide you on manufacturing methods, product design, materials selection, and packaging efficiencies.

From high-volume injection molding to custom products with complex component sourcing and assembly requirements, we are committed to finding the right solution for your project.

FAQs on Custom Manufacturing Services

How long does it typically take to manufacture a product?

Will I be able to see samples before production?

Once the production is completed, we will send you another set of samples to compare to the preproduction samples. If there are any deviations, we make the necessary corrections before the goods are delivered to the port.

How does the pricing work for custom manufacturing services?

We’ll share pricing options for ExWorks (picked up at the factory location) or FOB port (delivered to the overseas port in China or Vietnam).

One of the biggest factors in pricing is order quantity. We understand that you want to maximize profitability while maintaining the appropriate amount of inventory. Our team can provide you with estimates across a range of production quantities so that you can choose the option that works best for you.

Please note that any product development costs and shipping/freight forwarding expenses will not be included in your custom manufacturing quote; they will be quoted separately if they are part of the services we are providing for you.

Do you have a minimum order quantity?

Where do you manufacture products?

We work with manufacturing partners in mainland China and Vietnam to produce your products. We maintain close relationships with factory owners and senior management and regularly conduct site visits to ensure all production adheres to our high standards.

How do you ensure quality control during production?

We can also conduct tests to ensure that your materials will pass any required product safety tests and that the product maintains its integrity during shipping.

How can I be sure that my product isn’t copied and sold illegally?

We recommend consulting with an intellectual property attorney if you are interested in securing additional protections for your product. We are happy to make a recommendation from our network, so please feel free to ask!

What are GPI’s payment terms and methods?

Payment can be made via ACH, wire transfer, or corporate check.

Do you have any examples of products you have made?

Please check out our gallery for examples of products GPI has manufactured.

How Can We Help You?

Tell us about the product idea you want to design and manufacture!